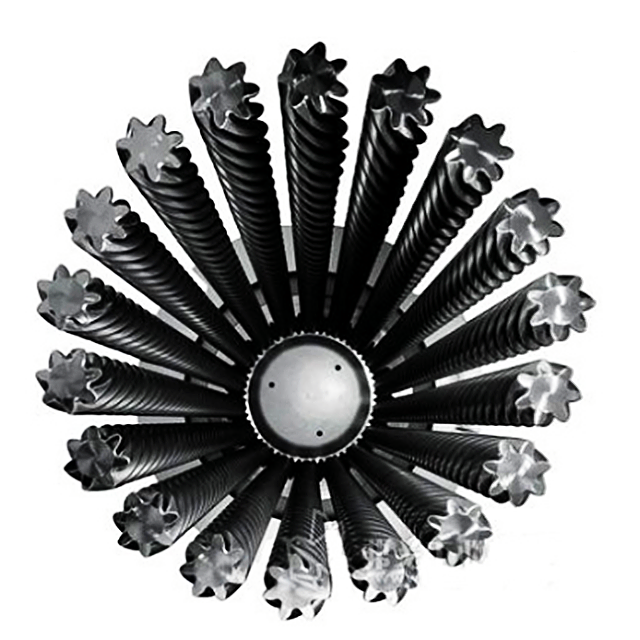

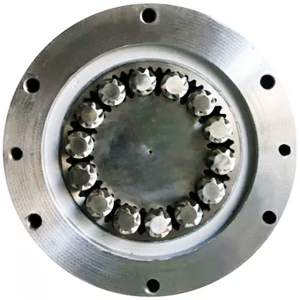

Planetary Screw Barrel for Extruder Machine

Technical Parameters of planetary screw barrel

Diameter: 15-300

L/D ratio:15-55

Or other according to requirement, we are rich experience in producing and designing for planetary screw barrel.

| Product Name | Planetary screw barrel |

| Material | 38 CrMoAlA(JIS SACM645); 42 CrMo(AISI 4140)Cr12MoV(JIS SKD-11);4Cr5MoSiV1(JIS SKD-61) |

| Nitrided Hardness | HV950°~1050° |

| Hardness after hardening and tempering | HB260 -290° |

| Nitrided Depth | 0.5~0.7mm |

| Nitrided Brittleness | Less than Grade 2 |

| Surface Roughness | Ra0.4 |

| Screw straightness | 0.015mm |

| Hardess of surface chromium-plating after Nitriding | HV≥950HV |

| Chromium plating Depth | 0.05~0.10mm |

| Alloy Depth | 3~5mm |

| Alloy hardness | HRC56°~65° |

| Alloy(bimetallic) | iron,nickel,tungsten,molybdenum |

| Types of screw barrel | Gradual type,mutant type,wave type,barrier type,double screen type,shunt type,separation type,exhaust type,pin type,mixed type,double-head type,three-head type,multi head type etc. |

Scope of application for planetary screw barrel

For good plasticizing effect,we have different designs of planetary screw barrel to meet customer's demand.Our factory manufactures with high-quality material, applying the method of hardening and tempering and nitriding, thus it enjoys the characteristics of long working life, wear resistance, and anti corrosion. Besides, the technique of hard alloy spraying or chrome plating can be used on the working surface of screw, which will make it have better using effectiveness.

The company adheres to the customer as the center, to strictly control the quality of the production process, the implementation of lean production management to ensure that the quality of the testing process continues to be effective, excellent product quality. To meet the requirements of different customers with efficient production capacity and timely delivery capacity. The company has many years engaged in the design of plastic machinery parts, processing of professional personnel, and can provide customers with door-to-door mapping, design, transformation, custom, and other services, and to undertake all kinds of wear and tear of the repair work.

We are a professional manufacturer of screw barrel.

Our company implements scientific management, well equipped with different kinds of advanced processing and inspection equipment. This provides a solid foundation for our quality products.

Packaging & Shipping

Product show

Our Exhibition

FAQ

Our advantages:

1. Screw and barrel for various models

2. Professional engineers design for you

3. Over 20-year exprience in this line

4. Insist on developing screw and barrel for more injection and extruder machine models

5. Main market: Southeast Asia,Eastern Europe, South America,Africa